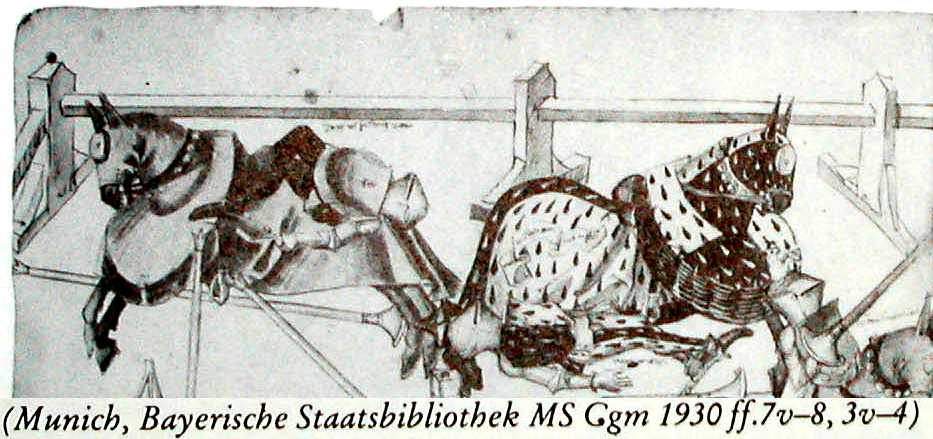

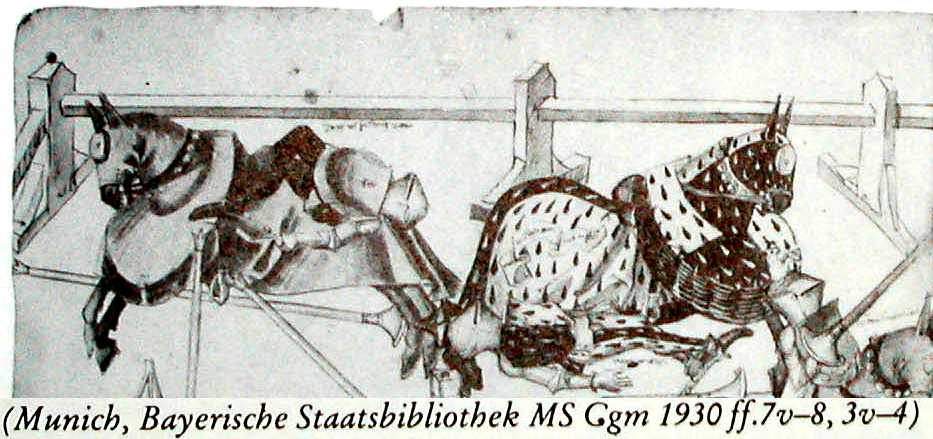

1. Detail of Manuscript Illustration

A Proper Tourney Fence

| The Oak (A&S Newsletter of Atlantia) | Sir Dafydd ap Gwystl |

| Issue #8 | kuijt@umiacs.umd.edu |

This is a design for a sturdy portable tournament fence based directly upon surviving manuscript illustrations of 15th and 16th century tournaments. The concept was inspired by Master Galicron du Cressy, who had the original idea of constructing such a fence. The design is based upon an illustration of a German civic joust from 1519. Figure 1 shows relevant detail of the illustration, taken from Tournaments (Barber and Barker, Weidenfeld & Nicolson, NY, 1989; p. 71).

1. Detail of Manuscript Illustration

| A few changes were necessary to allow the fence to be portable, not too heavy, and require no tools to take down and put up. The major innovation is the friction-fit design for locking the side rails to each other and to the side supports. The ends of the rails are cut at a shallow angle; the through-mortise in the side supports is taller than the width of a single rail, but less than the width of two rails. When the fence is put up, simply srnacking the end of each rail with a hammer will cinch up the previous joint tight. No fuss, and no precision woodworking is necessary. Figure 2 shows how the joint looks when the fence is set up. |  2. Friction Joint for Side Rails |

This fence has been tested rigorously at several tournaments. Its virtues are numerous. It is portable. The design is both flexible and modular-you can set it up in a myriad of ways, and combine fences from different groups to create much larger list areas. It is very sturdy, suffering collisions from dozens of fighters without collapse. Broken pieces can be repaired or replaced individually. It forms a rigid barrier, unlike the usual rope and stakes technique. It is expendable to virtually any size. It is completely authentic in appearance, and it looks fantastic. Finally, it is not particularly expensive -- on average, 100' of fence will cost less than $100. Since it is very durable, this should be a good investment for most baronies and large shires.

To approach this project you will need basic knowledge of wood: gluing, screwing, and sawing. The side rails require chiseling a through-mortise (a square hole through the piece of wood). This is fairly easy even if you've never tried it, but if you are a novice you should take care and get help from someone knowledgeable if possible. Making the corner posts is harder, and should not be attempted by novices. Luckily, it is possible to have a fully functional fence without corner posts by setting it up with entrances at the corners.

| To make each side rail 8' of 2x4 lumber |

To make each side post 5' of 2x6 lumber 2' of 2x3 lumber 6 drywall screws, 2 1/2" long 1/4" dowel, 12" long wood glue |

| To make each corner post 4' of 6x6 lumber 4' of 2x6 lumber 2' of 2x3 lumber wood glue |

Stock may be of whatever type of wood is cheapest. Choose straight pieces, and dry wood, but there is no reason to spend extra money to buy higher quality lumber. Carefully chosen pieces of construction-grade lumber will do ftne. It is worth your time to borrow a belt-sander to sand off any manufacturer stamps or markings. When I built my fence I bought spruce 2x6, 10' long; spruce 2x4, 8' long, and pressure-treated 6x6, 4' long. Each 2x6 became two side supports; each 6x6 became a single corner post. I could have saved some money by buying two 8' long 6x6, but the huge weight of the pieces made it impractical to work in my small basement shop.

1. Take an 8' long piece of 2x4 stock.

2. Make two cuts as shown on each end of the rail so that it tapers from its full width (3 1/2") to 1 1/2" over an 8" distance on both ends.

Note: rails can be any width desired; I chose 8' long as it will fit inside my minivan and full-sized pickup trucks, and on the roof-rack of most cars. If your transport vehicle can handle it, 10' rails would work fine.

Figure 3 illustrates how the joints should look on the ends of the side rails.

3. Cut two pieces of 2x6 stock, one 3' long for the upright and one 2' long for the base.

4. Take the 3' long piece and bevel the top end with two 45 degree cuts as shown. Make the cuts so that they don't quite meet, leaving the top slightly blunt.

| 5. Cut a through mortise centered in the 3' long piece as shown: 1

1/2" wide and 5" high, starting 26 1/2" from the bottom end

(i.e. from 26 1/2" to 31 1/2" from the square end). Cut the

mortise a little oversize in width (perhaps 1/8" or so extra) to

ensure that even the largest side rails will fit through the mortise.

6. Drill two holes with a long 1/4" drill bit through the width of the 3' piece about 3/4" above and below the mortise. Glue a 6" dowel in each of the two holes. Cut the dowels flush once the glue has dried. These dowels serve to reinforce the bottom and top of the mortise to prevent splitting. Make sure that the whole dowel is well slathered with glue before inserting it in the hole. 7. Now take the 2' long piece. Cut a notch in the side of this piece as shown below. The notch should be 5 1/2" wide and 2" deep. Note that 2x6 stock is only approximately 5 1/2" wide, and a tight fit is good here, so measure the width of the 3' piece exactly and cut the notch to that width. 8. Slather the notch with glue and insert the bottom (flat) end of the 3' piece. Drill pilot holes for two reinforcing screws as shown; use two drywall screws to reinforce the joint. 9. Cut the 2x3 stock into two pieces 10 1/2" long, with both ends of both pieces bevelled at 45 degrees. Slather the ends with glue and place them on the sides of the post as shown. Have a friend hold them in place while you drill pilot holes for the screws and then screw the angle supports down with two drywall screws each. Note: always drill pilot holes for the drywall screws, or the wood will split. Figure 4 shows a finished side support |

|

Figure 5 illustrates the details of corner post construction, with specific focus on the through-mortises and the end slots.

10. Cut a 4' long piece of 6x6 stock for the post. Bevel one end as shown with four 45 degree cuts.

|

11. Cut two 2' long pieces of 2x6 stock for the base. 12. Cut two through mortises in the post. Both are 1 1/2" square (cut a little oversize, as on the side posts). On one side the bottom of the mortise is 30" from the bottom of the 6x6; on the perpendicular side (NOT the opposite side) the bottom of the mortise is 33 1/2" from the bottom of the 6x6. This means that the two through-mortises will not intersect in the post. See Figure 5. 12. Cut two slots in the base of the 6x6. Each slot will be l 1/2" wide and 5 1/2" high., the two slots will cross each other as shown in Figure 5. 13. Now take the 2' long pieces of 2x6 stock. Cut a slot in one piece, centered in one side, 1 1/2" wide and 3 1/2" high as shown. Cut a slot in the other piece, centered in one side, 1 1/2" wide and 2" high. The two pieces should interlock on these slots to form an X, as shown in Figure 5. Adjust the slots so that the two pieces fit comfortably without binding. Also check the fit of both pieces into the slots cut in the end of the 6x6 and adjust as necessary. 14. Glue the base piece with the deeper slot into the base of the 6x6 with its slot opening down. This will form the permanent base of the corner post; the other base piece will be removable for transport. |

|

15. Cut the 2x3 stock into two pieces 10 1/2" long, with both ends of both pieces bevelled at 45 degrees, exactly as for a side post. Slather the ends with glue and place them on the sides of the post as shown. Have a friend hold them in place while you drill pilot holes for the screws and then screw the angle supports down with two drywall screws each. This should securely fasten the permanent base piece to the corner post. Check the fit of the removable base piece again and adjust if necessary.

Notes: In my area the only 6x6 stock available was pressure-treated lumber. This is acceptable, but tough to work with. No matter what you have, cutting the through mortises and the slots in the butt end of the 6x6 is the most work in the whole process. Take your time; don't rush it.

16. Take an 8' long piece of 2x4 stock.

17. Make an angled cut on one end as with the side rails, so that it tapers from its full width (31/2") to 1 1/2" over an 8" distance on one end. On the other end cut a square piece out so the end of the rail is a 1 1/2" square tenon, 8" long.

18. Reinforce the end of the tenon as shown by putting a short dowel through it.

19. Carefully cut a mortise through the end of the tenon for a tusk tenon, as shown in Figure 6. The tusk tenon will lock the rail in place in use.

| 20. Cut six or eight end-blocks to hold the side rail rigid at

entrances. These blocks are cut out of scrap 2x4 stock. They are 8"

long and taper from the full width (3 1/2") at one end to 1 1/2"

at the other as shown in Figure 7. They are used as stop blocks to cinch

up the joint when only a single rail ends at a side support (which is what

happens at openings in the fence).

|

|

21. Cut a small tusk tenon out of hardwood to lock each corner rail after it passes through its corner post. The tenon should be large enough to fit the mortise cut in step 19.

Webmaster's addendum:

Here are two photos of the tourney fence set up and in use. For those wanting the drawings in PowerPoint, you can download them here. For those wanting metric measurements, the plans in use in Drachenwald can be found here.

|

|